أرسل لنا رسالة

earth mining ball mill

Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 In total, 165 scenarios were simulated. When the mills charge comprising 60% of small balls and 40% of big balls, mill speed has the greatest influence on power

Planetary Ball Mill Process in Aspect of Milling

2014年4月28日 Iván Darío Mora-Vergara. Daniel R. Molina-V. Víctor Baldovino. View. Show abstract. Research into the Influence of the Planetary Ball Mill Rotation Frequency on the Limiting Value of the

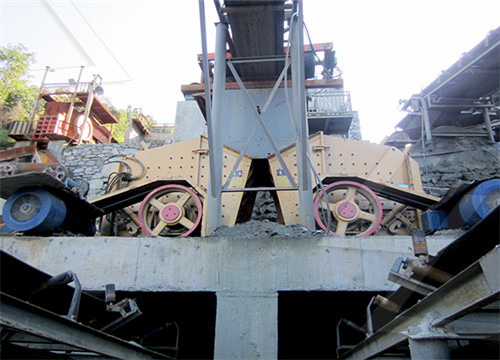

Ball Mill Prominer (Shanghai) Mining Technology Co.,Ltd.

Ball Mill. This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building

Ball Mill Explained saVRee

Closed-Circuit Or Open-CircuitCritical SpeedGeneral NotesBall mills may operate in a closed-circuit, or open-circuit. Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reduction. A typical closed system grinds the ore between two to three times. Hydro-cyclones installed directly after the ball mill ensure only over-sized material is returned to the b...

High Energy Ball Mills Instead of Planetary Ball Mills

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within a very short process

The advantages and disadvantages of ball mills

2020年9月21日 The advantages and disadvantages of ball mills. 09-21-20; 2,501 Views; icon 0; Because the method used to grind the fine material in the beneficiation equipment

Grinding mills for mining and minerals

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill

Grinding Ball Design MetallurgistMineral

2017年11月6日 Grinding Ball Design. Table of Contents. Grinding balls are essential mechanical components in ball and semiautogenous (SAG) mills. Their function is crushing and grinding ore rocks weighing up to 45 kg

What Is Ball Mill? Eastman Rock Crusher

2023年3月16日 1) The dry and wet ball mills have different discharge methods. The discharge outlet of the dry ball mill is a straight cylinder type, which adopts grate plate

How to Make a Ball Mill: 12 Steps (with Pictures)

2020年8月10日 Position the pieces so that the base sits at a height of 4” (10.16 cm). You can secure the pieces in place with some

Grinding Mills Mineral Processing Equipment

2022年3月18日 High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日 Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining) is 3.6 m, and the internal diameter is 3.4 m. The mass of the drum without the grinding media is 84 Mg.

Ball Mill Explained saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged. Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’.

[Hot Item] Mining Use Continuous Wet Ball Mill with Good

1 Mining Use Continuous Wet Ball Mill with Good Price, Find Details and Price about Ball Mill Grinding Ball Mill from Mining Use Continuous Wet Ball Mill with Good Price Henan Hongji Mine Machinery Co., Ltd. Print This Page. Home ManufacturingProcessing Machinery Building Material Making Machinery Cement Making Machine

grinding mill/ultrafine mill/ball grinding mill/ultrafine

2022年9月30日 Various industrial grinding mills for sale, stone powder processing equipment basement from China! Grind all kinds of ores into high-valued superfine powder!Action speak louder than words.Why not contact us now? Superior quality, impeccable service--Shanghai Clirik Machinery Co.,Ltd, your customized stone powder

Northern Star halts Pogo gold mine in Alaska MINING.COM

2023年3月15日 The Pogo mine entered commercial production in 2006 and was later acquired by the company in 2018. The deposit currently contains probable reserves totalling 1.8 million oz. from 6.6 million

Ball mill SlideShare

2015年4月24日 5. The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery. Grinding can be carried out in either wet or dry but the former is carried out at low speeds. The advantages of

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher,

Overflow Bearing Small Mini Wet Dry Mine Laboratory Ball

Tipo: Ball Mill Tipo di motore: AC Motor Potenza del motore: 5.5KW Rotationl Velocità: 30-40 Applicazione: Miniera Materiale: Limestone, Feldspar, Kaolin, Cement

sbmchina/sbm how much is a ball mill mining.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

[Hot Item] Mining Use Continuous Wet Ball Mill with Good

1 Mining Use Continuous Wet Ball Mill with Good Price, Find Details and Price about Ball Mill Grinding Ball Mill from Mining Use Continuous Wet Ball Mill with Good Price Henan Hongji Mine Machinery Co., Ltd. Print This Page. Home ManufacturingProcessing Machinery Building Material Making Machinery Cement Making Machine

Ball milling: a green technology for the

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide

Ball Mill Parameter SelectionCalculation JXSC

2019年8月30日 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness,

sbmchina/sbm how much is a ball mill mining.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Quartz Limestone Mine Ultrafine Ball Mill Grinding

Quartz Limestone Mine Ultrafine Ball Mill Grinding Machine,Trova i Dettagli su Small Scale Mining Ball Mill, Ore Grinding Machine Ball Mill da Quartz Limestone Mine Ultrafine Ball Mill Grinding Machine Henan Fuyuan Machinery Manufacturing Co., Ltd.

Michael Guan auf LinkedIn: Hello. We are Professional

Hello. We are Professional Mining Grinding Solution Provider with 34 years experience in China. Main products: Mill Liner, Crusher Jaw Plate, Concave, Casting Ball, which are widely used in Cement, Mining, Chemical Industries, etc. https://lnkd/gt3WJfBi. MobileWhatsApp: +86 .

Hoogwaardige 900X3000 900*1800 kleine mini

Hoogwaardige 900X3000 900*1800 kleine mini-dieselmotor Gypsum Gold Mijnbouwmachines Limestone Quartz Zircon Copper Ore Chrome Wet Ball Prijs molenmachine,Vind Details over Kleine kogelmolen met dieselmotor, Ball Mill Limestone van Hoogwaardige 900X3000 900*1800 kleine mini-dieselmotor Gypsum Gold

Winning the Metal: Ore Mills of the West Western

The earliest, and simplest method of crushing ore was the use of arrastras. When enough capital was available, stamp mills replaced arrastras at most mines. The following sections take a look at various types of stamp mills, the most common milling facilities at mines of the frontier West. The Trench mill at Silver City, Nevada 1877.

Michael Guan على LinkedIn: Hello. We are Professional

Hello. We are Professional Mining Grinding Solution Provider with 34 years experience in China. Main products: Mill Liner, Crusher Jaw Plate, Concave, Casting Professional Mining Grinding Solution Provider (Manufacturer) with 34 years experience in China!

Ball Mill Rejects Line Isolation Mining, MineralsMetals

Discover severe service valve solutions to isolate your ball mill rejects line. Clarkson KGD and KGA+ knife gate valves cut through slurry and foreign materials to provide long life, zero leakage, bidirectional sealing. During maintenance events, Clarkson valves offer rapid, on-site repair to minimize downtime.